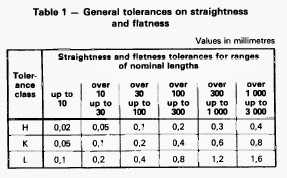

In contrast to the standards replaced bs en 10259 introduces tolerances for flatness of sheet plate and cut lengths with both a normal and special range.

Sheet metal flatness tolerance standard.

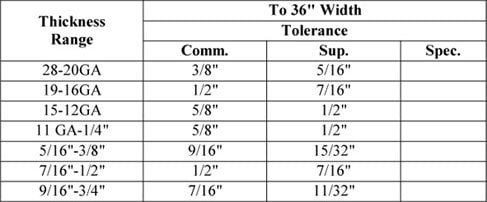

4 for widths over 6 ft these tolerances alloy for any 6 ft of total width.

Tight tolerances raise the cost of manufacturing significantly.

Tolerances of 010 should be considered minimum.

During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges.

1989 general tolerances part 2.

Linear tolerances should be held as loose as possible.

Standard astm mill toleranes flatness hot dipped metallic oated sheet cut lengths over 12 in width specified to tenion leveled standard of flatness astm 924 97a specified minimum thickness inch over 019 thru 032 incl.

There is a larger tolerance range above 3000mm lengths.

For sheet metal parts iso 2768 mk is used.

It is important to remember that these tolerances apply to the mill produced product where they have specialized equipment to perform flattening operations.

It applies to the following specifications that describe carbon steel structural steel and high strength low alloy steel hsla furnished as hot rolled sheet and cold rolled sheet.

1 1 this specification covers the general requirements for steel sheet in coils and cut lengths.

5 short span flatness is the deviation from flat over full span for spans 2 ft and less 2 tx51 is a general designation for the following stress relieved tempers.

The resulting bend angle variation and sometimes the required adjustment to the flat layout contributes to the reason that machined parts typical tolerance of 0 002 in can routinely have tighter tolerances than precision sheet metal parts typical tolerance of 0 010 in.

Specifications a414 a414m a424 a424m a606 a606m a659 a659m a794 a794m a1008 a1008m a1011 a1011m and a1039.

T351 t451 t651 t851 t7351 and t7651.

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances.

Practical tolerances vary according to the design requirements.

Sheet metal guage tolerances.

Sheet metal tolerances should not be tighter than necessary to make the part functional.

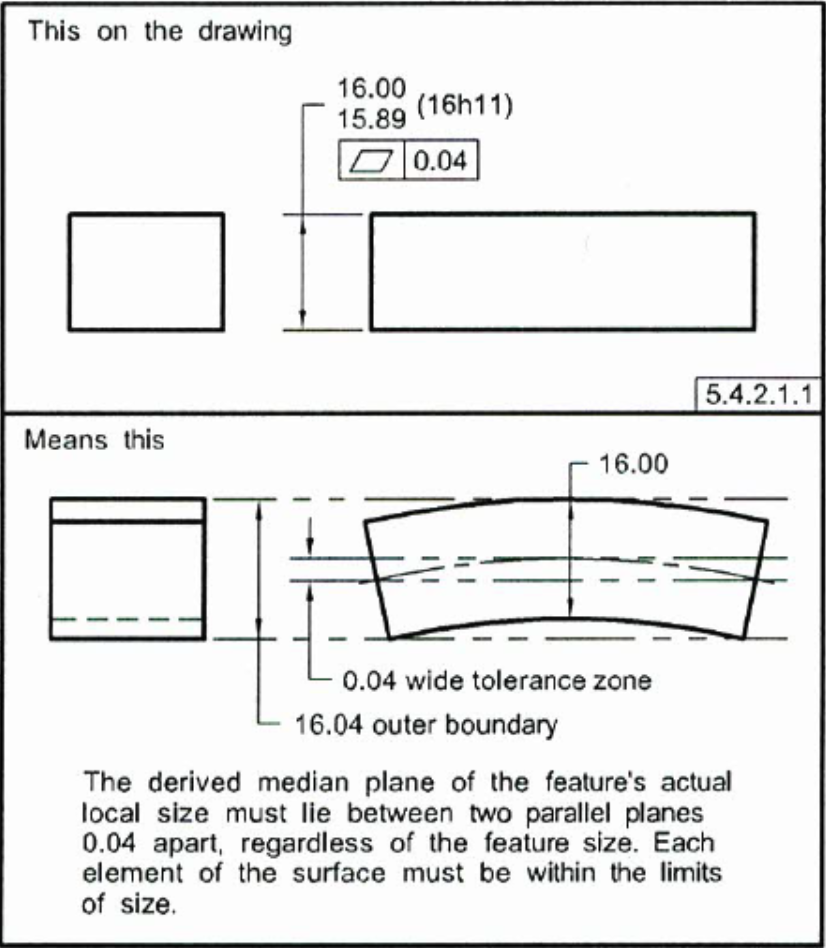

Geometrical tolerances for features without individual tolerance indications.

Flatness and edge waviness tolerances.

Flatness tolerances for sheet are published only for full size sheets.

Flatness tolerance thickness width maximum deviation in in from a horizontal inches inches flat surface in inches 0 062 60 0 40 60 0 50 0 062 60 0 40 60 0 50 stretcher leveled sheets specified to stretcher leveled standard of flatness exclusive of 1 4 2 3 4 and full hard tem pers of 200 and 300 series grades.

Tolerance class is defined as per design requirements and manufacturing capability.